06-Mar-2023 - Last updated on 06-Mar-2023 at 14:56 GMT

Related tags Meat & Seafood tech Dairy Rotary Welding Horn

At Interfood, the focus has been on full line solutions and the benefits of an integrated approach to processors’ slicing requirements.

As Tom Foran – divisional manager of slicing for Interfood – explained, one of the most important factors in a successful line solution is the ability and ease for each component and module on the line to communicate with the others.

“This is a fundamental consideration in the development of automated slicing lines to ensure maximum efficiency,” he continued. “An example of this is the Weber/Textor full retail bacon line solution.

“With the proven Textor TS700/750 slicers at its heart, a full slicing line solution can encompass pressing, slicing and packaging right through to end-of line inspection and final case/crate packing, offering an option ideally suited to high-speed retail bacon production.”

The Weber/Textor Power Control System provides complete line integration, working in tandem with ‘Weber One Control’ to give line operators the ability to view performance, interrogate and control individual line modules from any touchscreen on the line.

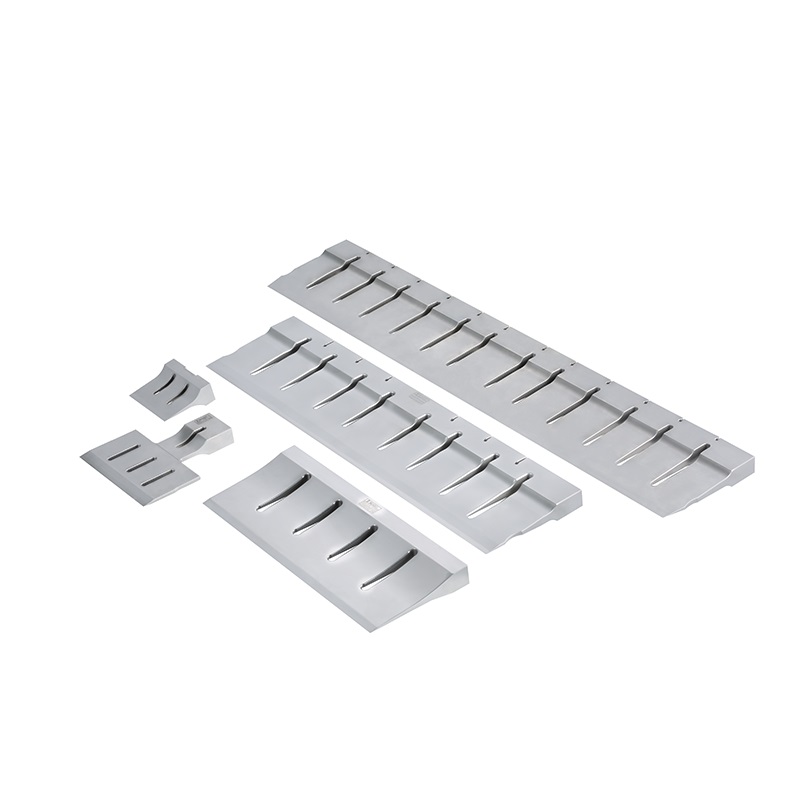

Of course, the success of any slicing operation comes down to its components. In this example, Textor (and parent company Weber) operate an in-house blade manufacturing and technology department.

By developing their own blades, they can ensure that their machines have the right tools for the job to meet the needs of specific applications, from all types of bacon – including wet cure and premium dry – in a range of portion presentations.

“It’s about optimising efficiency and control and that is best achieved through ensuring that the different components in the line communicate effectively,” Foran added. “This enables optimisation of product flow and performance which ultimately contributes significantly to a profitable operation. Of course, you also need the best available base components to build the line for which Interfood is well known.”

While the world of meat processing sees the line of share of innovation when it comes to developments in slicing and cutting technology, we mustn’t forget that the dairy sector is also a major beneficiary of the advancements. But unlike meat, cheese cutting often requires an extra level of finesse not required in the cutting of beef and poultry.

Cheese is traditionally hard to cut in manufacturing – cutting with a knife can result in breakage and even the drag of the knife can cause damage. The solution put forward by food machinery manufacturer Elliptical Design is to use ultrasonic technology when cutting.

Ultrasonic uses energy from microscopic vibrations of a blade to pass easily through the material and offers a more effective solution for cutting cheese and other food products. When paired with automation, ultrasonic technology can deliver precise and accurate cutting for cheese manufacturers while eliminating wastage from damage and also improve aesthetics.

To support the implementation of ultrasonic cutting in its work with an unnamed cheese maker, Elliptical Design bought industrial robots into the process using machinery from TM Robotics. For this system, TM Robotics supplied the TV1000H 6-axis industrial robot.

Within this process, the robot picks up a ten-kilogram piece of cheese and moves it onto a weigh station and then a cutting station. There, it is cut in half using precise and accurate ultrasonic technology.

While elliptical Design said the collaboration yielded great results, fine tuning the robots’ vision system was a challenge. It all ties back into the idea of a fully integrated cutting line – information from one part of the line is passed along the rest of the production process to produced greater accuracy and prevent wastage.

“Shibaura Machine robots are generally easy to integrate with vision systems,” explained Nigel Smith, managing director of TM Robotics. “The challenge here was to ensure that the robot was picking up cheese in the right place and being able to put it down as accurately as needed — there’s a very slim margin for error in plastic tote placing.

“When the cheese is placed on the conveyor its actually still slightly soft. Rather than a round shape, it has a slightly flat side. Using ou