Lithoz GmbH and the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory have signed a Cooperative Research and Development Agreement (CRADA) to use Lithoz’s 3D printing technology to further explore the processing and additive manufacturing of non-oxide ceramics.

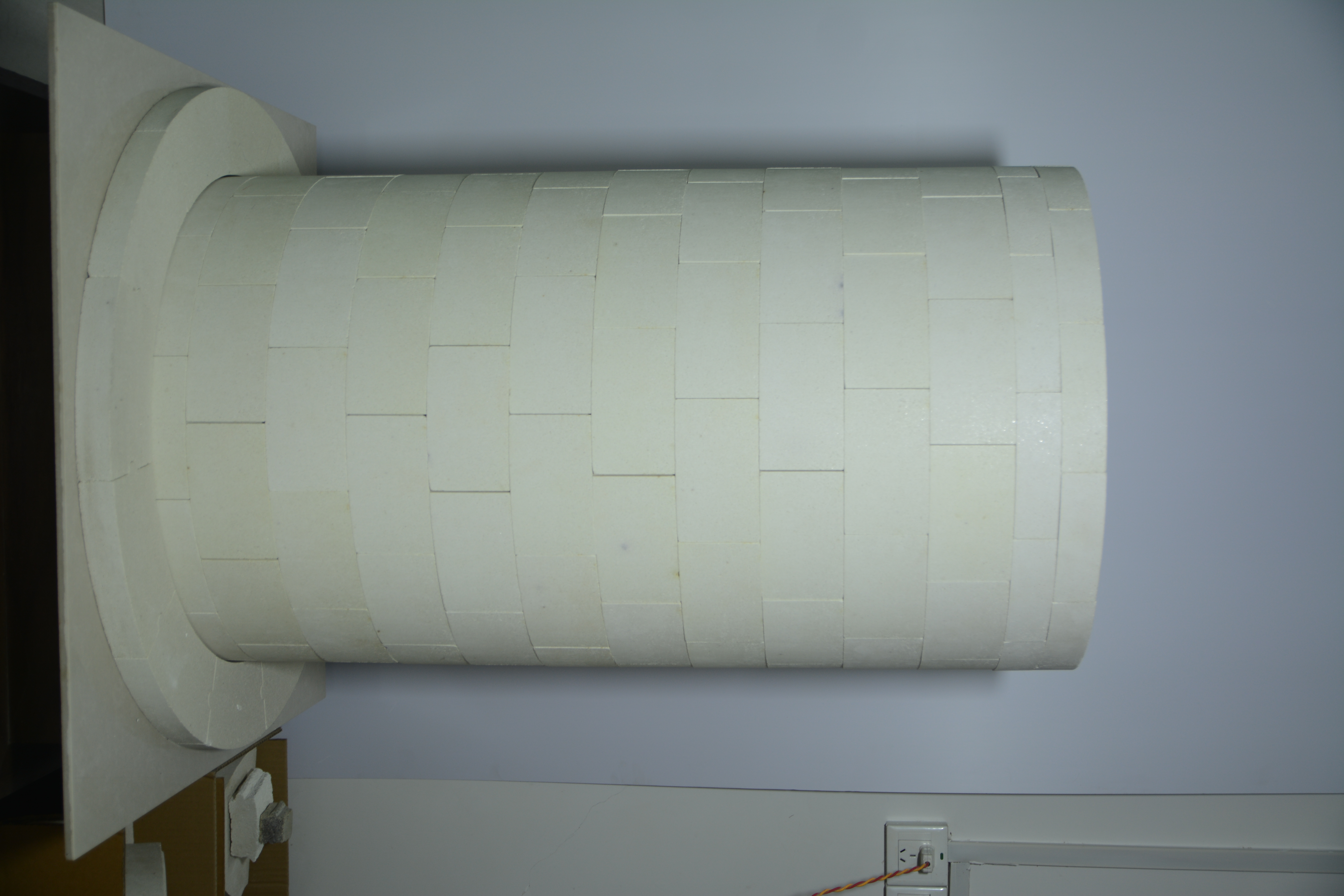

Based on Laser-Induced Slipcasting (LIS) technology, the Lithoz 3D printer uses laser slurry drying, or net shaping, technology to guide computer-controlled light amplification by stimulated emission of radiation that desiccate liquid-suspended controlled layers of solids. The goal of the cooperative agreement is development of the technology to shape non-oxide ceramics with high-refractive indexes, such as silicon carbide, for use in extreme temperature applications. Industrial Application Of Ceramics

Lithoz recently launched its LIS technology to produce parts that are far more complex in geometry and larger in scale than can be achieved using conventional moulding techniques. By incorporating intricate inner channels and 3D-printable complex designs, the parts it can produce are lighter and more efficient when compared with current methods. This technology is also capable of increasing the range of materials that can be printed by processing dark ceramics, such as silicon carbide and silicon nitride, in a way that is unachievable with other processes.

The goal of this project is to scale up the production of ultra-high temperature ceramic parts to an industrial level. The team will look to develop this technology by assessing its technical capabilities using a common oxide-ceramic material. This will involve printing and debinding the primary material – such as silicon nitride and silicon carbide, two highly in-demand substances for aerospace applications – from the moulded component. Using heat, the substance will be formed into a solid material in a process known as sintering. The performance and properties of the printed materials will then be tested.

“This project will build on ORNL’s years of research in developing and testing high-temperature materials and ceramics,” said Corson Cramer, Extreme Environment Materials Processing Group staff scientist at ORNL. “By combining our expertise with Lithoz 3D printing capabilities, we have the potential to change the concept of high-temperature ceramics processing for heat exchange, aerospace and defense applications.”

UT-Battelle manages ORNL for the DOE’s Office of Science, the single largest supporter of basic research in the physical sciences in the United States. The Office of Science is working to address some of the most pressing challenges of our time. Research for advanced manufacturing projects is being performed at the DOE Manufacturing Demonstration Facility. The facility is home to the MDF Consortium, a nationwide group of collaborators working with ORNL to advance U.S. manufacturing technologies under the guidance of the DOE Advanced Materials & Manufacturing Technologies Office. For more information, please visit energy.gov/science and energy.gov/eere/ammto/ammto-programs.

Please use one of the following formats to cite this article in your essay, paper or report:

Lithoz GmbH. (2023, December 06). Lithoz and Oak Ridge National Laboratory Team Up to Advance 3D-Printed Non-oxide Ceramics for Extreme Temperature Applications. AZoM. Retrieved on January 09, 2024 from https://www.azom.com/news.aspx?newsID=62269.

Lithoz GmbH. "Lithoz and Oak Ridge National Laboratory Team Up to Advance 3D-Printed Non-oxide Ceramics for Extreme Temperature Applications". AZoM. 09 January 2024. <https://www.azom.com/news.aspx?newsID=62269>.

Lithoz GmbH. "Lithoz and Oak Ridge National Laboratory Team Up to Advance 3D-Printed Non-oxide Ceramics for Extreme Temperature Applications". AZoM. https://www.azom.com/news.aspx?newsID=62269. (accessed January 09, 2024).

Lithoz GmbH. 2023. Lithoz and Oak Ridge National Laboratory Team Up to Advance 3D-Printed Non-oxide Ceramics for Extreme Temperature Applications. AZoM, viewed 09 January 2024, https://www.azom.com/news.aspx?newsID=62269.

Do you have a review, update or anything you would like to add to this news story?

Dr. Craig Johnson & Dr. Kate Vanderburgh

AZoMaterials speaks with Dr. Craig Johnson, Director of Research Core Facilities, and Dr. Kate Vanderburgh, Scanning Electron Microscope (SEM) and X-Ray Microscopy Manager, about the Materials Characterization Core (MCC) facility at Drexel University.

In this interview, we speak with John Weaver from Pfizer about the importance of process safety testing.

In this interview, AZoM speaks to Bruker Optics about the different ways IR light can be used in semiconductors.

This article describes the features and applications of the Optical precision micrometer - optoCONTROL2520.

Discover the SAVANNAH Raman module, the most compact OEM Raman module.

Specac’s Power Hydraulic Press Series are available in 8 Ton, 15 Ton and 25 Ton load configurations.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

AZoM.com - An AZoNetwork Site

Alumina Ceramic Specific Heat Owned and operated by AZoNetwork, © 2000-2024